Precision Overburden Injection Backed by Experience

AST’s overburden injection capabilities are configured to adapt to a wide range of site conditions. We’ve completed more than 1,000 injection projects across the U.S., Canada, and Europe—each one guided by data-driven design and field-tested methodology.

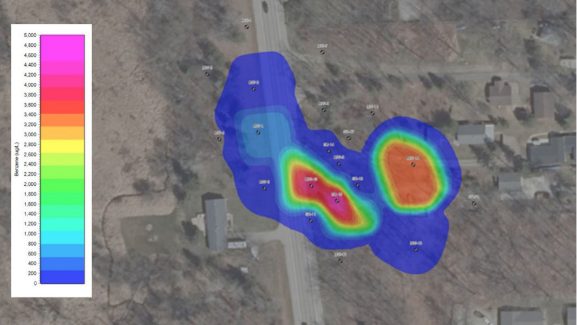

- Custom injection planning based on qHRSC and Remedial Design Characterization

- Targeted reagent placement using proprietary tooling and refined injection procedures

- In-house fabricated electric injection systems designed for flexibility and control

- Compatibility with slurries >30% solids, oxidizers, reducers, and emulsified amendments

- Flow rates adjustable from <5 gpm to 70 gpm to suit site-specific formation properties

- Real-time parameter monitoring and QA/QC for reagent distribution verification

We tailor each injection design and field approach to the site’s specific lithology, injection depth(s), geochemistry, and product chemistry to ensure optimal performance- from fine-grained soils to high-permeability overburden units (including fill and glacial till).

Why AST’s Overburden Injection Works

Overburden remediation isn’t one-size-fits-all. AST’s approach stands out because we:

- Design for complexity: Custom systems allow us to adapt to soil variability on the fly

- Deliver with precision: Narrow-zone targeting ensures reagents reach impacted intervals

- Optimize chemistry: Selection and dosing are fine-tuned based on real-time site data

- Minimize waste: Controlled flow and pressure prevent over-application or loss to non-target zones

- Support closure: Performance data and distribution verification reduce regulatory friction

Whether you’re facing petroleum hydrocarbons, chlorinated solvents, or emerging contaminants, AST’s overburden injection service gets treatment to the contaminant—and moves your site toward closure faster.