An advanced in-situ remediation product that merges activated carbon + ZVI (BOS 100®) with slow-degrading electron donors and peptides to catalyze the degradation of chlorinated solvents.

How It Works

CAT 100® combines the proven BOS 100® platform with engineered biotechnology to create a next-generation in-situ remedy capable of degrading significantly more contaminant mass per unit dose.

Mechanism of Action:

- Contaminant Binding: Chlorinated solvents adsorb to the activated carbon matrix and contact chemically fused zero-valent iron (ZVI)

- Electron Pump: Complex carbohydrates and peptides degrade slowly, generating electrons

- Catalytic Reaction: Electrons are transferred through the carbon-iron matrix to the electrostatically bound contaminant, where it is degraded

- Iron Conservation: Unlike conventional ZVI, iron is not significantly or rapidly consumed because of electron generation and shuttling

- Iron Surface Area: The manufacturing process creates a massive iron surface dispersed throughout the AC, allowing for far greater mass removal per unit of iron

This system promotes both adsorption and catalytic reductive dechlorination, enabling sustained contaminant breakdown with fewer injections and better longevity.

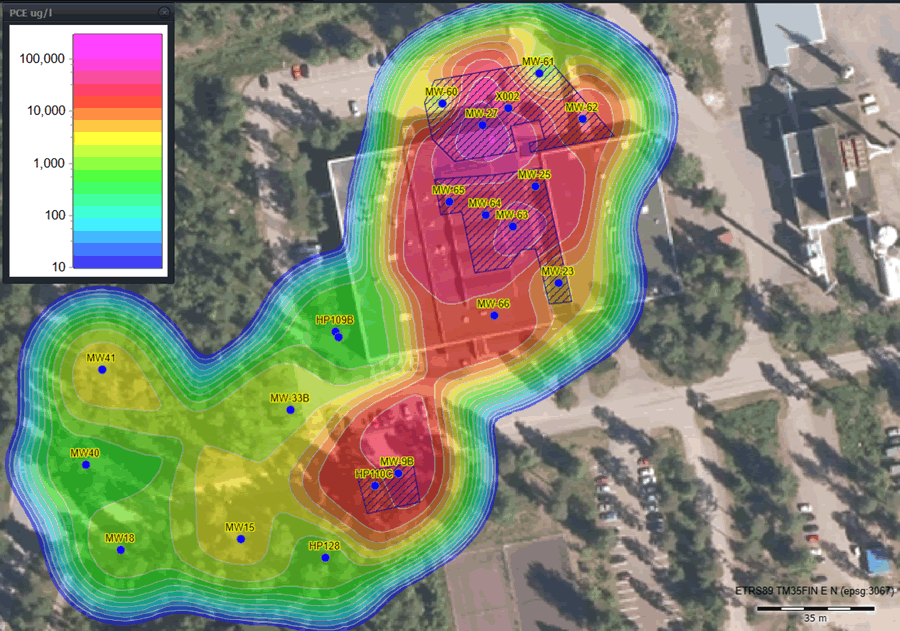

Performance Results

CAT 100 has been deployed at sites across the United States, northern Europe, and South Africa.

- DNAPL Source Treatment: Documented >90% mass reduction in high-concentration source areas within 6–12 months

- Longevity: Active treatment effects observed 5+ years post-injection in challenging, mixed-mass sites

- Mass Efficiency: Field results demonstrate far higher degradation than stoichiometric iron demand models would predict

Common Applications

- CVOC source zones with high mass or DNAPL

- Commingled contaminant plumes (e.g., CVOCs + petroleum)

- Sites with rebound issues post-excavation or SVE

- Regulatory-driven sites requiring aggressive, sustained action

Typical Site Types

- Aerospace and defense facilities

- Industrial solvent handling plants

- Superfund and RCRA corrective action sites

- Rail yards and maintenance depots

- Chlorinated solvent manufacturing and degreasing operations

Product Comparison

| Feature / Spec | BOS 100® | BOS 200® | BOS 200+® | CAT 100® |

|---|---|---|---|---|

| Target Contaminants | Chlorinated solvents (TCE, PCE, DCE, VC) | Petroleum hydrocarbons (BTEX, TPH, LNAPL) | Complex PHC sites: LNAPL, MTBE, glycols, etc. | CVOCs, DNAPL, mixed chlorinated solvent mass |

| Primary Mechanism | Adsorption + abiotic reductive dechlorination (ZVI) | Adsorption + aerobic biodegradation | Adsorption + enhanced bio (aerobic & anaerobic) | Adsorption + catalytic degradation + engineered bio |

| Activated Carbon Type | Powdered AC with micro-scale ZVI | Powdered activated carbon | Agglomerated ultra-pure AC for microbial colonization | Conductive AC matrix embedded with ZVI |

| Biological Component | None | Native stimulation + nutrient blend | Proprietary microbial consortia + nutrient system | Engineered donors + peptides feeding catalytic process |

| Reductive Capacity | Yes – ZVI-driven | No | No | Yes – Catalytic ZVI (non-stoichiometric) |

| Biological Activity | Limited | Aerobic only | Aerobic + anaerobic | Aerobic + anaerobic |

| Persistence / Longevity | 5–10+ years | 3–5 years | 2–4+ years | 2–4+ years with extended catalytic activity |

| Ideal Use Cases | CVOC plumes, low-perm zones, regulatory-driven sites | BTEX/LNAPL plumes, polishing after excavation | Persistent LNAPL, smear zones, PRBs | DNAPL source zones, high-mass CVOC, mixed plumes |

| Compatible Conditions | Anaerobic required for ZVI activity | Aerobic preferred | Works in aerobic/anaerobic settings | Functions in both aerobic and anaerobic environments |

| Iron Demand / Consumption | Stoichiometric | N/A | N/A | Catalytic – minimal iron depletion |

| Delivery Methods | Direct push, trench, injection wells, PRBs | Direct push, wells, soil mixing | Direct push, wells, PRBs, mixing | Direct push, wells, soil mixing |

| Field Proven? | Yes – 500+ CVOC sites | Yes – widespread PHC remediation | Yes – complex PHC/LNAPL sites | Yes – used in U.S. + Europe at complex DNAPL sites |