BOS 100® is an in-situ remediation amendment made of activated carbon impregnated with zero-valent iron (ZVI). It is designed to treat chlorinated solvents in groundwater by both adsorption and chemical reduction.

How It Works

BOS 100® is a Trap & Treat® in situ remediation technology specifically designed to degrade chlorinated solvents. It is a unique material manufactured from high grade virgin carbons (intended for use in food or drinking water applications). The food grade carbon is impregnated with metallic iron formed under reducing conditions at a temperature of roughly 850 degrees C. At this temperature, as the metallic iron is formed it partially dissolves into the carbon forming a new and unique material with properties of both the carbon and iron but with capabilities exceeding ZVI in terms of rates of destruction and the range of halogenated compounds it can degrade. As manufactured, the product contains roughly 6.5% (wt) metallic iron. Reaction end products include dissolved iron, chloride, and a series of unregulated gases such as ethylene and methane. The product is insensitive to groundwater geochemistry (e.g. pH, oxidation-reduction potential).

Mechanism:

- Adsorption: Contaminants are rapidly sorbed to the activated carbon.

- Reduction: Once adsorbed, the metalic iron reacts with CVOCs, breaking them down via abiotic reductive dechlorination.

- Long-Term Stability: Treated compounds are destroyed, not just contained—minimizing rebound.

- A single injection can provide long-term, sustained remediation, even in low-permeability zone

Performance Results

- Field data confirms rapid contaminant mass removal with minimal rebound.

- BOS 100® has achieved >90% contaminant reduction in dozens of real-world sites.

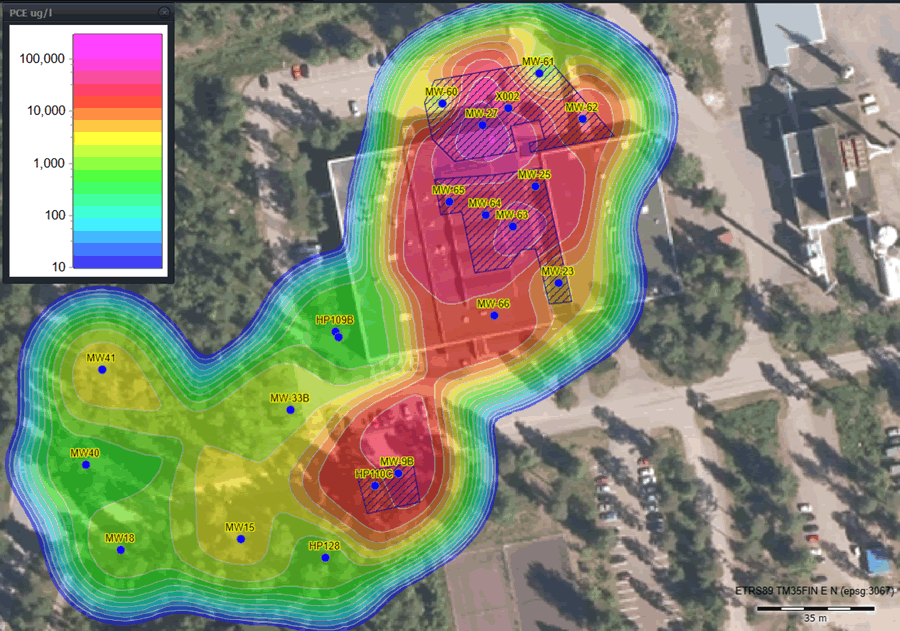

- TCE Plume Collapse: 95% reduction within 6 months – Industrial site, Midwest U.S.

- PCE Reduction: ND levels achieved in <12 months – Dry cleaner site, Southeast

- Longevity: Active performance documented for 10+ years post-injection

Common applications

- TCE, PCE, DCE, VC plumes

- Low permeability zones

- Sites requiring a low-maintenance, long-term remedy

- Regulatory pressure for active treatment vs. MNA

Example site types

- Dry cleaners

- Aerospace/defense facilities

- Industrial manufacturing

- Solvent storage and transfer facilities

- Superfund or RCRA corrective action

Product Comparison

| Feature / Spec | BOS 100® | BOS 200® | BOS 200+® | CAT 100® |

|---|---|---|---|---|

| Target Contaminants | Chlorinated solvents (TCE, PCE, DCE, VC) | Petroleum hydrocarbons (BTEX, TPH, LNAPL) | Complex PHC sites: LNAPL, MTBE, glycols, etc. | CVOCs, DNAPL, mixed chlorinated solvent mass |

| Primary Mechanism | Adsorption + abiotic reductive dechlorination (ZVI) | Adsorption + aerobic biodegradation | Adsorption + enhanced bio (aerobic & anaerobic) | Adsorption + catalytic degradation + engineered bio |

| Activated Carbon Type | Powdered AC with micro-scale ZVI | Powdered activated carbon | Agglomerated ultra-pure AC for microbial colonization | Conductive AC matrix embedded with ZVI |

| Biological Component | None | Native stimulation + nutrient blend | Proprietary microbial consortia + nutrient system | Engineered donors + peptides feeding catalytic process |

| Reductive Capacity | Yes – ZVI-driven | No | No | Yes – Catalytic ZVI (non-stoichiometric) |

| Biological Activity | Limited | Aerobic only | Aerobic + anaerobic | Aerobic + anaerobic |

| Persistence / Longevity | 5–10+ years | 3–5 years | 2–4+ years | 2–4+ years with extended catalytic activity |

| Ideal Use Cases | CVOC plumes, low-perm zones, regulatory-driven sites | BTEX/LNAPL plumes, polishing after excavation | Persistent LNAPL, smear zones, PRBs | DNAPL source zones, high-mass CVOC, mixed plumes |

| Compatible Conditions | Anaerobic required for ZVI activity | Aerobic preferred | Works in aerobic/anaerobic settings | Functions in both aerobic and anaerobic environments |

| Iron Demand / Consumption | Stoichiometric | N/A | N/A | Catalytic – minimal iron depletion |

| Delivery Methods | Direct push, trench, injection wells, PRBs | Direct push, wells, soil mixing | Direct push, wells, PRBs, mixing | Direct push, wells, soil mixing |

| Field Proven? | Yes – 500+ CVOC sites | Yes – widespread PHC remediation | Yes – complex PHC/LNAPL sites | Yes – used in U.S. + Europe at complex DNAPL sites |