Designing Barriers That Actually Work

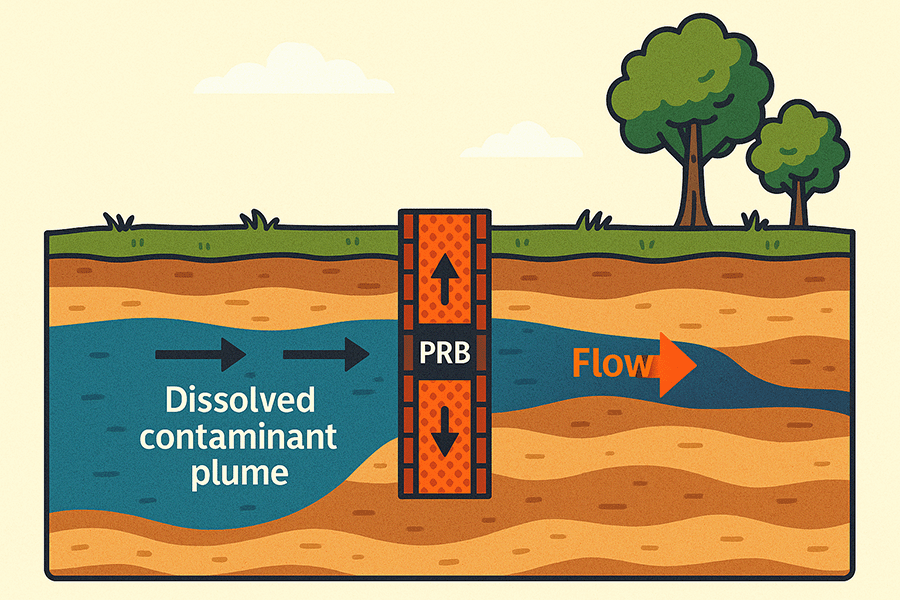

A PRB’s effectiveness depends on one thing above all: whether it intersects and treats the majority of the contaminant mass flux. That requires more than just drawing a line on a map and injecting one row of points in the field.

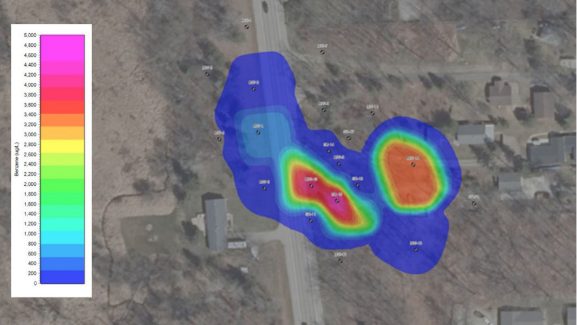

At AST, we approach PRB design with a deep focus on mass flux characterization. Instead of relying on average concentrations or generic assumptions, we use our quantitative high-resolution conceptual site model (CSM) to understand:

- Variability in subsurface flow

- Distribution of contaminant mass

- Preferential pathways that could bypass the barrier

- Product reaction and residency time

This data-driven strategy helps us avoid underperformance and ensures that the PRB actually does its job—whether the goal is full plume bisection, partial containment, strategic source isolation, or order of magnitude (OOM) reduction in mass transport.

Deployment Methods That Fit the Site

We’ve implemented PRBs through multiple emplacement techniques, depending on site constraints:

- Direct-push injection for targeted subsurface barriers without major surface disruption

- GeoTAP for DPT-inaccessible geology and repeated injection needs (e.g., mass flux, schedule, access)

- Continuous trenching for large-scale or shallow plume bisection

- Induced-gradient zones to drive plume interaction with reactive materials

- Trap & Treat® technologies to promote long-term degradation of hydrocarbons and chlorinated solvents

Many clients deploy PRBs as part of a cost-effective hybrid strategy—using passive PRBs to protect sensitive receptors, establish boundary line containment, or cut off plume migration while addressing source areas separately.

When to Consider a PRB

- You need quick protection for nearby sensitive receptors or property lines

- Site-wide remediation is cost-prohibitive or unnecessary

- There’s a need to buy time before full-scale remediation is funded or approved

- You want to reduce long-term O&M costs associated with pump-and-treat or active systems

Let’s Deploy It Right the First Time

A PRB isn’t a “set it and forget it” solution unless it is designed based on real-world groundwater flow, geochemistry, and mass flux data. AST brings the tools and experience to ensure your PRB delivers measurable, long-lasting performance.